Need To Do An Inventory Audit? Read This First

Inventory audits may not be the most glamorous task on your to-do list, but they’re one of the smartest moves you can make to keep your ecommerce business running smoothly.

Think of them like a health check-up for your operations: a routine step that catches small issues before they grow into expensive problems. Without audits, it’s easy for stock records and reality to drift apart, and that gap can lead to overselling, missed revenue, or customer frustration.

The good news? An audit doesn’t have to be overwhelming. With a clear process (and the right tools), you can turn what feels like a headache into a straightforward, confidence-building exercise.

This guide will walk you through the steps, highlight common mistakes to avoid, and show you how tools like Goflow’s Inventory History can save hours of detective work during reconciliation.

What Is an Inventory Audit and Why Does It Matter?

An inventory audit is the process of checking that your physical stock matches your records. It’s about making sure what your system says you have is actually sitting on the shelf.

Here’s why it matters:

Prevents costly errors like overselling or unexpected stockouts.

Protects profitability by uncovering shrinkage, miscounts, or supplier mistakes.

Builds trust with customers (and your accounting team).

Improves forecasting by giving you a more accurate baseline.

Think about it this way: if your records show 25 units of a best-selling product, but you only have 20 on hand, you could easily oversell. That leads to refunds, frustrated customers, and lost revenue.

An audit helps you catch those problems before they cause bigger headaches.

Step 1: Set Clear Objectives

Not every audit has the same purpose. Start by deciding what you want to learn:

Accuracy: Do your records match what’s in stock?

Shrinkage: Are products disappearing due to theft, damage, or errors?

Financial reporting: Do you need precise numbers for year-end accounts?

Process gaps: Are there weaknesses in how items are received, stored, or recorded?

Clear goals help you choose the right audit method and scope.

Example: You might run a full audit for annual reporting, but stick to cycle counts for high-value SKUs during the year.

Step 2: Prepare Your Records

Before you start counting, make sure your records are up to date.

Pull reports from your inventory system.

Log all recent sales, returns, and receipts.

Confirm transfers between warehouses or locations are complete.

Starting with outdated data is one of the fastest ways to throw your audit off track.

If you’re working across multiple warehouses, bookmark this helpful guide: Multiple Warehouses? No Problem. Here’s What You Need To Know.

Step 3: Choose the Right Audit Method

There’s no single “right” way to audit. Your approach should match your goals, your team size, and your inventory complexity. Choosing the right method upfront will save time and ensure you actually get useful insights out of the process.

Here are the main approaches:

Full physical count: Every item is counted in one sweep. Best for year-end or quarterly audits when precision matters most. Downside? It’s time-intensive and may require temporarily pausing operations.

Cycle counting: Instead of shutting down to count everything, you rotate through smaller sections of your catalog on a schedule (daily, weekly, or monthly). This spreads the workload and keeps records more accurate year-round.

Spot checks: Quick, random counts of specific SKUs. Ideal for validating system accuracy between major audits or keeping tabs on fast-moving products.

Pro Tip: Many growing businesses start with full counts but shift to cycle counting once order volume increases. That way, audits become part of the regular rhythm of operations rather than a dreaded, all-hands-on-deck event.

Step 4: Conduct the Audit

This is where the counting begins. A few tips to keep things accurate and efficient:

Count in teams of two (one counts, one records).

Move methodically through categories or warehouse zones.

Use barcode scanners or software when possible to reduce human error.

Keep distractions low. This is precision work and it deserves focus.

The more consistent your process, the fewer discrepancies you’ll have to untangle later.

Step 5: Reconcile Any Discrepancies

Once the counting is done, compare your physical counts to your system records.

If something doesn’t line up, dig into the “why”:

Receiving errors

Misplaced items

Theft or shrinkage

Data entry mistakes

Adjust your records as needed, but don’t stop there. Find the root cause so it doesn’t happen again.

This is where Goflow’s Inventory History can save you serious time. You’ll see a full record of every action taken on a product, from sales to returns to transfers to adjustments, making it much easier to trace discrepancies back to their source.

Common Mistakes to Avoid

Audits can go off track quickly if you’re not careful. Here are the traps to steer clear of:

Skipping system updates before the audit: If recent sales, returns, or transfers aren’t logged, you’ll end up chasing false discrepancies.

Relying only on manual notes without backups: Paper checklists or scribbled tallies can easily get lost or misread. Always use a digital backup. Ideally, that’s an automated inventory management platform, as a simple spreadsheet often isn’t enough to handle most modern ecommerce inventory tracking.

Delaying audits for too long: The longer you wait, the harder it is to pinpoint when errors happened. Small problems snowball into bigger mysteries.

Failing to investigate discrepancies: It’s not enough to just “adjust” numbers. If you don’t find out why the mismatch happened, you’ll face the same issue again next time.

See these as opportunities to improve your business operations in the long term, making sure that future audits will be leaner, more accurate and less time-consuming.

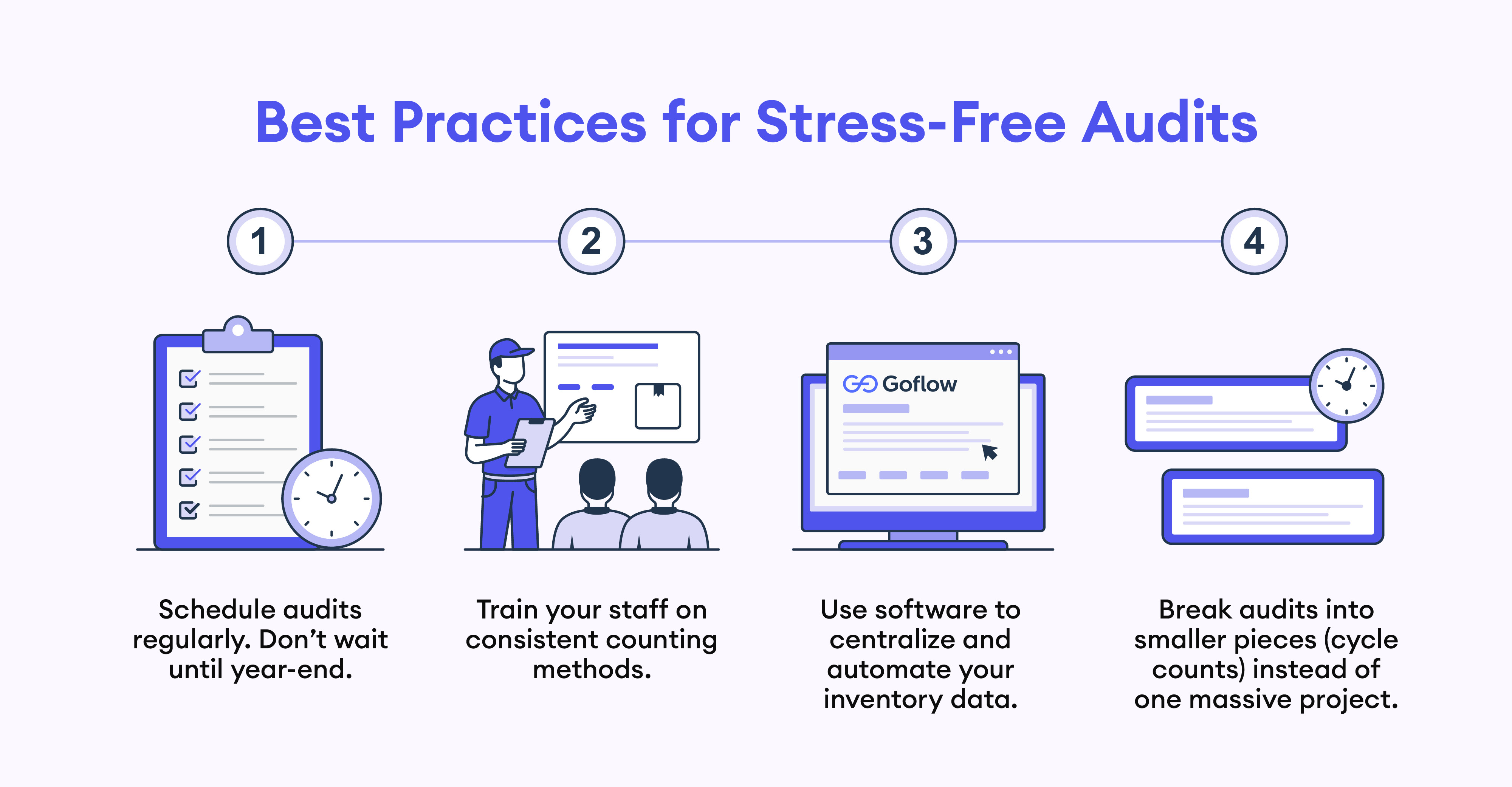

Cheat Sheet: Best Practices for Stress-Free Audits

Schedule audits regularly. Don’t wait until year-end.

Train your staff on consistent counting methods.

Use software to centralize and automate your inventory data.

Break audits into smaller pieces (cycle counts) instead of one massive project.

The natural next step after auditing your inventory is to analyze the data and determine whether you’re doubling down on the products that really move the needle. This is called an ABC Analysis, and we have a step-by-step guide to conducting one right here.

Final Thoughts

Inventory audits don’t have to be the dreaded chore many sellers imagine. Done right, they’re less about counting boxes and more about strengthening the backbone of your business.

By setting clear objectives, preparing your records, choosing the audit method that fits your workflow, and avoiding common pitfalls, you’ll create a process that feels manageable. Over time, audits become less about fire-fighting and more about building confidence in your numbers.

The payoff? Better accuracy, fewer customer complaints, smarter forecasting, and ultimately, stronger profitability.

And when it comes to reconciliation, don’t forget you don’t have to do all the detective work alone. Goflow’s Inventory History gives you a detailed timeline of every action on each SKU, so instead of digging through spreadsheets and emails, you can zero in on the source of a discrepancy in seconds.

Ready to see how much smoother your next audit can be? Book a live customized demo and see Goflow in action.