Multiple Warehouses? No Problem. Here’s What You Need to Know

According to the U.S. Census Bureau, ecommerce sales in the USA increased by more than 32% in 2020, driven in part by the COVID-19 pandemic.¹ This surge in online shopping has continued since, with the growing ecommerce market generating 1.2 trillion USD in 2024 and forecast to generate 1.8 trillion USD by 2029.²

As ecommerce sales skyrocket, many online sellers are expanding to multiple warehouses. But managing inventory across locations can quickly become a logistical nightmare. It’s essential to have the right tools in place, including a dynamic system capable of syncing sales and stock between each location.

In this guide, we’ll examine some of the pros and cons of expanding to multiple warehouses, then cover some essential strategies and best practices. By the end of this post, you’ll be equipped with actionable tips you can use to simplify and optimize your multi-warehouse inventory management and run your business more smoothly.

The Advantages and Challenges of Managing Multiple Warehouses

Having multiple warehouses makes inventory management more complicated, but it also brings with it many advantages. Let's look at both sides of the coin and consider the pros and cons.

Multi-Warehouse Advantages | Multi-Warehouse Challenges |

|

|

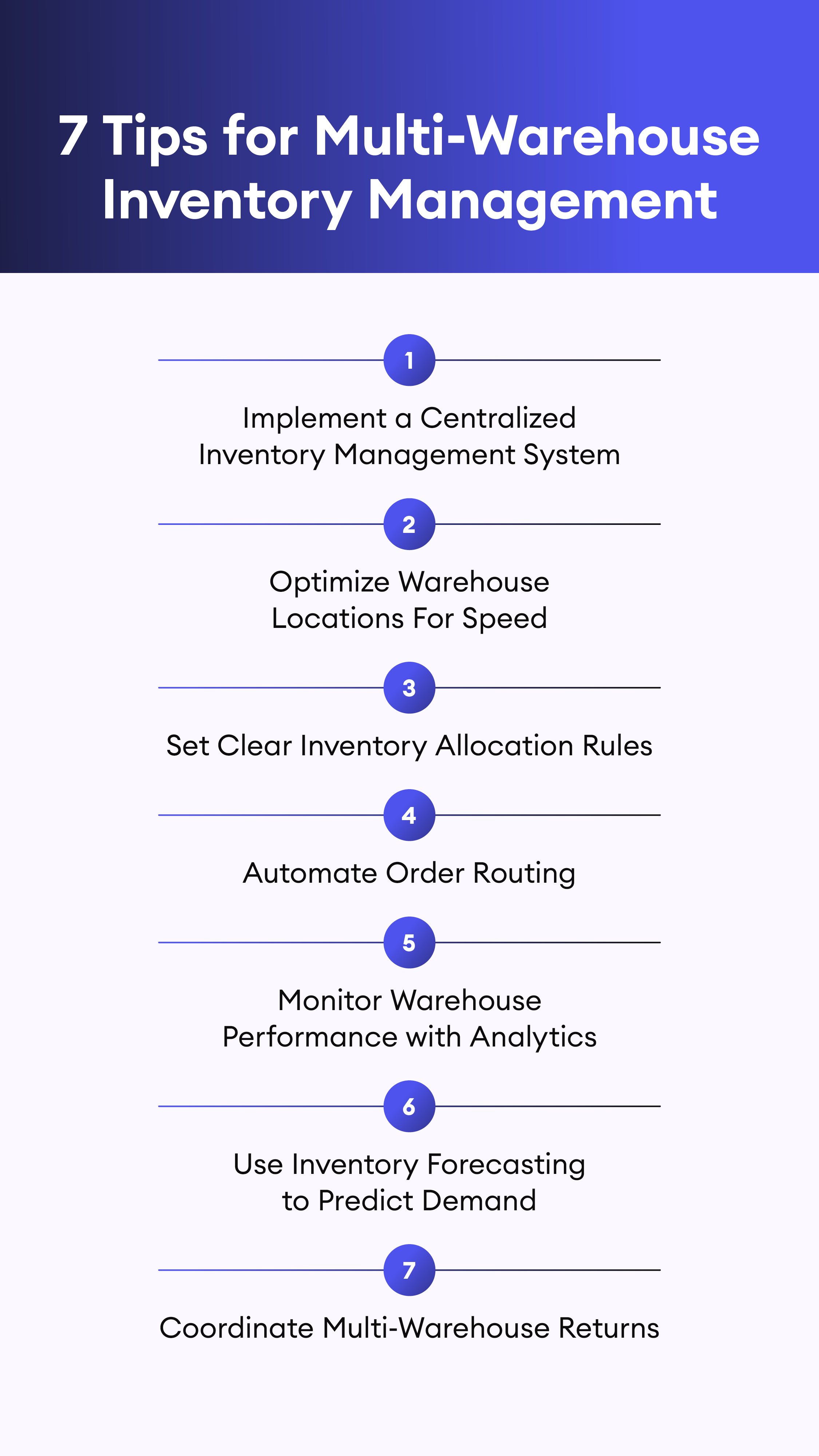

7 Key Tips for Multi-Warehouse Inventory Management

As you expand your business to include multiple warehouses, it becomes more important than ever to make sure your systems and processes are streamlined and working efficiently.

Let’s look at 7 tips and best practices to help you scale up to multiple warehouses the right way and avoid the most common pitfalls.

1. Implement a Centralized Inventory Management System

Having a centralized inventory management system is crucial if you have multiple warehouses.

This type of system keeps track of your inventory in real-time across all your locations, so you always know what’s in stock. You can avoid overselling items that are out of stock in one place and prevent stockouts by moving inventory around as needed. Plus, a centralized system makes other inventory tasks, such as stock transfers and purchase orders, much easier.

With a centralized inventory management system equipped with inventory syncing tools, such as Goflow, you’ll always have a bird’s-eye view of your stock levels. You’ll be able to make informed decisions about ordering and replenishing, so you can transfer stock between warehouses seamlessly and distribute available stock to efficiently meet demand.

Goflow offers real-time syncing, and many other features to help you keep your inventory organized. No more guessing games or spreadsheets - everything you need is in one place.

Case Study: How Jeannie N Mini Streamlines Inventory Management Across Multiple WarehousesJeannie N Mini LLC is a kids boutique store in Orange County, California, operating in both brick-and-mortar and online form. With products available on multiple marketplaces including Amazon, Nordstrom, Target and Macy’s, Jeannie N Mini LLC sells everything from toddlers shoes to baby toys to organic teas and skincare. The owner, Jeannie Yoon, chose Goflow because she was searching for a tool with the ability to manage multiple aspects of the business seamlessly within one platform - including real-time syncing inventory across multiple warehouses. Goflow allows Jeannie to manage and fulfill orders more effectively - across multiple platforms. To learn more about how this company uses Goflow, see the case study for more details. |

2. Optimize Warehouse Locations For Speed

Shoppers want their items, fast! Consumer expectations for fast delivery are high, and they are only continuing to grow.

According to a CapitalOne Shopping study:³

86% of consumers consider “fast delivery” within two days.

80% of consumers expect retailers to offer same-day delivery.

Reducing shipping costs and times is one of the most effective ways you can make your customers happier. But if you’re like most ecommerce sellers, you don’t really have a key customer base - you sell your products everywhere. So, how do you optimize for better shipping times? You pay close attention to where your warehouses are.

Choose strategic warehouse locations that will allow you to fulfill orders fast and cheap, regardless of where your customers are ordering from.

Look for warehouse locations close to major cities and offer access to ocean ports, major roadways and railroads.

The more accessible and well-connected the location, the better.

If the items you’re selling are perishable, it’s even more important to choose a warehouse location that’ll help you get them where they need to be faster.

3. Set Clear Inventory Allocation Rules

Inventory allocation is the practice of distributing available stock across warehouses to efficiently meet demand. This is an important part of keeping your inventory balanced, so products are evenly distributed and no location is overstocked or understocked.

You can use demand trends to determine which products should be stocked in each specific warehouse. Plus, you can employ forecasting, using past sales data, trends and seasonal demand levels to predict future inventory needs for each warehouse.

For example, an outdoor sports company may decide to stock more snow boots, winter coats and ski goggles in their Colorado warehouse, and more snorkeling equipment and swimsuits in their Florida warehouse.

A national retailer might stock more inventory in warehouses located near major metropolitan areas where demand is higher.

Establishing safety stock levels and replenishment strategies is also very important to prevent stockouts and make sure you can always meet customer demand.

4. Automate Order Routing

Your centralized system should be set up with automatic order routing, so it will send each order to the best fulfillment center based on defined rules and algorithms.

This will allow you to:

Reduce shipping costs and speed up delivery.

Decrease the risk of human error.

Ensure orders are fulfilled quickly and efficiently.

Goflow’s order routing tools help you out by automatically assigning orders to the warehouse closest to the customer’s delivery address, cutting down your shipping time and cost.

For example:

A California-based customer orders sunglasses from your online store.

The order routing tool automatically assigns the order to the warehouse closest to the customer’s delivery address.

The sunglasses ship from your West Coast warehouse, ensuring quick delivery and lower costs.

The automatic order routing system can take into consideration a wide range of factors, including inventory levels and shipping costs - it’s up to you to choose the rules it follows. For example, you can customize it to automatically select warehouses based on specific criteria such as order size, product type or special handling requirements.

It’ll work behind the scenes to maximise efficiency and reduce delivery times - resulting in substantial savings for every order processed.

5. Monitor Warehouse Performance with Analytics

Analyzing your data will help you find more ways to be efficient and save money. Some of the KPIs you’ll want to track include:

Order accuracy

Pick-and-pack times

Inventory turnover rates

Shipping costs

Keep a close eye on the key performance indicators (KPIs) for each of your warehouses, such as order accuracy, pick-and-pack times, inventory turnover rates and shipping costs.

Goflow’s reporting tools will give you a complete picture of your inventory levels and other important metrics for all your locations, so you can make smart choices based on the data. With one click, you can bring up a full inventory value report by warehouse or as a total of inventory across your entire ecommerce ecosystem. These analytics let you compare how your different warehouses are performing and find best practices to use across the board.

6. Use Inventory Forecasting to Predict Demand

Accurate demand forecasting is super important for managing inventory across multiple warehouses. By using advanced forecasting tools and looking at past sales data, businesses can predict changes in demand and adjust their inventory levels accordingly. This will help with:

Meeting customer demand.

Keeping costs down.

Maximizing efficiency.

Planning ahead & responding quickly to changes.

To make demand forecasting even more accurate, you can also consider things like seasonality, market trends and promotional activities. Plus, real-time data and analytics can provide valuable insights into current demand patterns, allowing your business to achieve optimal inventory levels across multiple warehouses and stay ahead of the competition.

By taking these variables into account, you can fine-tune your inventory levels with even more precision. This proactive approach helps prevent stockouts (which lead to lost sales and unhappy customers) and overstocking (which ties up money and increases storage costs).

To learn more about inventory forecasting, check out our helpful resource: Inventory Forecasting Guide: How to Predict Demand.

7. Coordinate Multi-Warehouse Returns

Having multiple warehouses doesn’t just make things complicated when shipping out items, it also complicates the process of receiving returns.

How should you handle this challenge?

Develop a clear and consistent system for handling returns across all warehouses.

Consider designating specific warehouses for handling returns or use a system to automatically route returns to the best location.

Ensure clear communication and coordination between warehouses for smooth and efficient returns handling.

Ideally, returns are handled according to a clear process, no matter which location they end up in.

The More Warehouses You Have, the More Organized You Need to Be

In this article, we covered some essential approaches to consider when selling across multiple warehouses. Managing inventory across multiple warehouses may be complex, but with the right strategies and tools you can reduce costs, improve efficiency and delight your customers.

Remember: effective inventory management is an ongoing process, requiring continuous monitoring, analysis and adjustment.

A solution like Goflow, with real-time syncing and advanced order routing, can be a game-changer when it comes to handling a multi-warehouse ecommerce business.

Start today by scheduling a demo!

¹ Coronavirus pandemic turbocharges online sales, which were up more than 31% in just three months: https://www.cnbc.com/2020/08/18/e-commerce-sales-grew-more-than-30percent-between-q1-and-q2.html

² Revenue of the ecommerce industry in the U.S. 2019-2029: https://www.statista.com/statistics/272391/us-retail-e-commerce-sales-forecast/

³ Same Day Delivery Statistics: https://capitaloneshopping.com/research/same-day-delivery-statistics/#:~:text=80%25%20of%20consumers%20expect%20retailers,expect%20free%20same%2Dday%20delivery.