Order Cycle Time: What Is it and Why Does It Matter?

When your customer clicks “Buy Now,” the clock starts ticking.

Every moment between purchase and delivery impacts your reputation, and your revenue.

Today’s customers expect fast, seamless fulfillment. In fact, 21% of online shoppers abandon their carts when delivery times are too slow.¹ That’s why tracking and improving Order Cycle Time is essential for any Ecommerce brand that wants to stay competitive.

In this post, we’ll cover what Order Cycle Time is, how to calculate it, why it matters for your inventory and fulfillment strategy, and five actionable ways you can improve it.

What is Order Cycle Time?

Let’s start by clarifying what we mean by Order Cycle Time.

This metric measures the total time it takes from when a customer clicks “Buy Now” and places their order to when that order is delivered.

It answers a simple but vital question:

“How fast do we ship and deliver once an order comes in?”

For brands selling finished goods (like skincare, snacks, or home goods), Order Cycle Time tracks everything post-purchase:

Order processing

Warehouse picking

Packing

Shipping

Final delivery

It doesn’t include sourcing raw materials or manufacturing time.

Order Cycle Time vs. Lead Time

Order Cycle Time is essentially a type of lead time, specifically from the customer’s perspective. It measures how long it takes for a buyer to receive their order after placing it with the seller.

While lead time can also apply to internal supply chain processes (like restocking inventory from a supplier), Order Cycle Time focuses solely on the post-purchase delivery window.

It’s also important to distinguish Order Cycle Time from Fulfillment Time, which only measures how long it takes to process and ship an order, not deliver it.

In short: Order Cycle Time = Customer-Facing Lead Time

This distinction matters because while all of these metrics impact fulfillment efficiency, they track different parts of the product journey.

How to Calculate Order Cycle Time

Here’s the formula:

Order Cycle Time = (Delivery Date – Order Date) / Total Orders Shipped

Let’s define each part:

Order Date: When the customer places their order

Delivery Date: When the customer receives their order

Total Orders Shipped: The number of orders you’re averaging during a given time period

Most businesses calculate Order Cycle Time weekly, monthly, or quarterly. The result is typically expressed in days or hours, depending on your shipping speed.

Real-World Example:

Let’s say you sell a line of premium skincare products. A typical order might look like this:

Step | Time |

Order placed | 10 a.m. Monday |

Processed + shipped | 4 p.m. Monday |

Delivered | 2 p.m. Wednesday |

Order Cycle Time | ~2 days |

Tracking this across hundreds of orders helps you monitor average performance and spot slowdowns.

Why Order Cycle Time Matters

A fast and predictable order cycle time creates a ripple effect across your entire business. Here’s how:

Faster Inventory Turns

When products move quickly from your warehouse to the customer, your inventory turnover rate improves. This means:

Less capital tied up in slow-moving stock

Reduced need for warehouse space

Lower risk of product obsolescence (especially in food, beauty, or seasonal categories)

Happier Customers and Better Reviews

In Ecommerce, speed equals satisfaction. When customers receive their orders promptly, they’re more likely to:

Leave positive reviews

Make repeat purchases

Recommend your brand to others

A short, reliable cycle time builds trust - and loyalty.

Smarter Forecasting

Knowing your order cycle time helps you better predict:

When to reorder

How much stock to keep on hand

How promotional spikes will impact operations

Lower Operating Costs

A streamlined cycle means fewer surprises. You’ll reduce:

Emergency rush shipping fees

Holding costs for excess inventory

Labor costs tied to inefficient processes

Protecting Your Amazon Account Health

Amazon’s Account Health Rating uses metrics like Perfect Order Rate to evaluate your seller performance. Amazon considers a Perfect Order one that’s delivered on time, with no issues (like cancellations or returns).

A slow or inconsistent order cycle time can lead to:

Lower “Perfect Order Rate”

Ineligibility for sales-boosting programs like Seller Fulfilled Prime (SFP)

Even account suspension in serious cases

If you rely on Amazon as a sales channel, keeping your order cycle time consistent, and ideally fast, is crucial for both visibility and long-term success.

5 Practical Ways to Improve Your Order Cycle Time

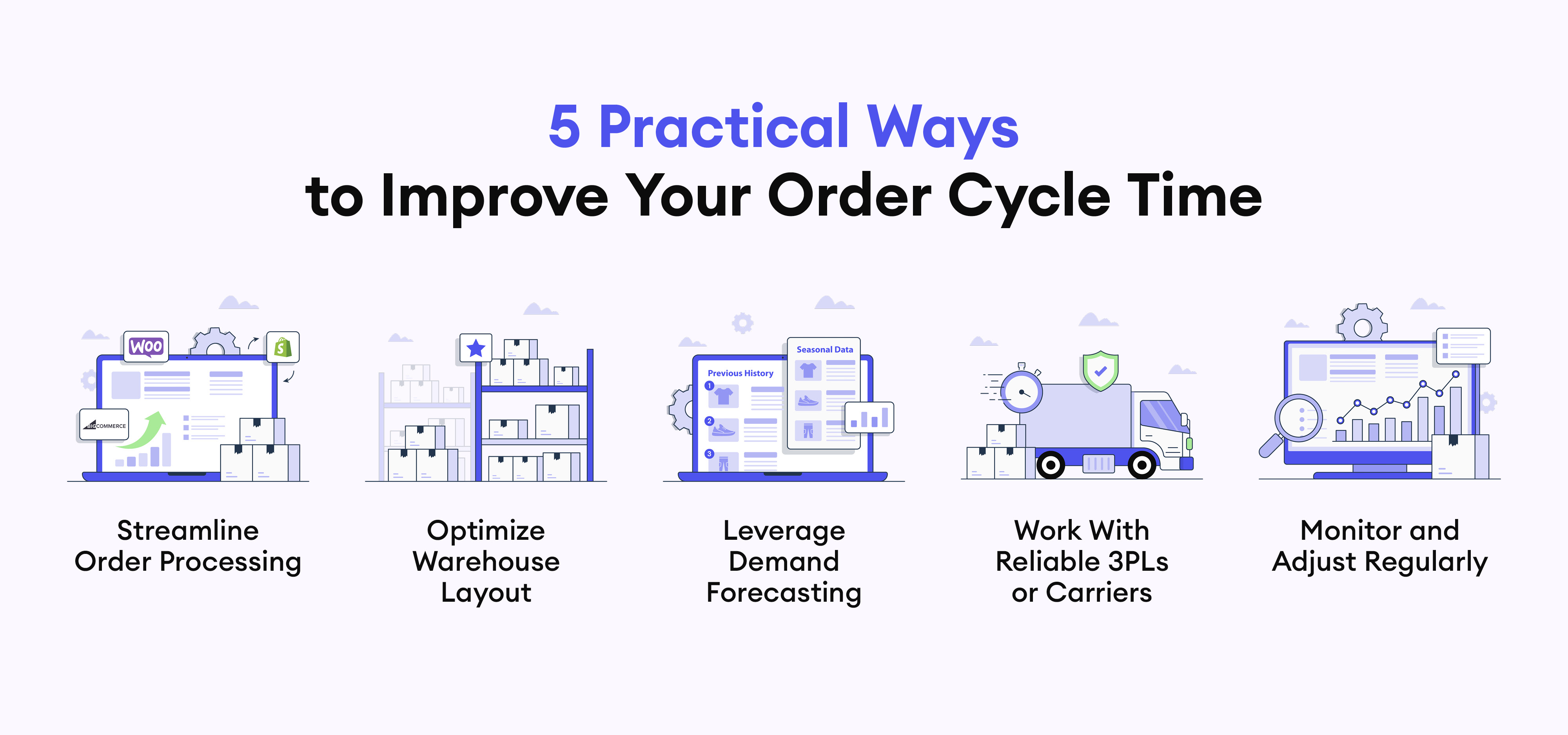

5 Practical Ways to Improve Your Order Cycle Time

For many DTC brands, a 1–2 day Order Cycle Time is the gold standard. But more important than speed is consistency.

Here are five proven ways to streamline your cycle time:

1. Streamline Order Processing

Use automation tools or integrate your Ecommerce platform (like Shopify, BigCommerce or WooCommerce) with your 3PL. This eliminates manual delays and speeds up fulfillment from the moment an order is placed.

2. Optimize Warehouse Layout

Make your top-selling SKUs easily accessible to reduce pick time. Group products that are frequently bought together to speed up fulfillment.

3. Leverage Demand Forecasting

Avoid cycle time delays caused by stockouts. Use historical sales data and seasonality trends to maintain optimal stock levels.

4. Work With Reliable 3PLs or Carriers

Your partners can make or break your cycle time. Choose a 3PL or shipping carrier that offers fast, transparent, and consistent delivery services. Choose fulfillment providers and carriers that offer:

Consistent SLAs

Real-time tracking

Proven on-time delivery rates

5. Monitor and Adjust Regularly

Track your average order cycle time monthly or weekly. If it starts creeping up, dig into where the bottleneck is, whether it’s processing delays, packing issues, or carrier slowdowns.

Further Reading:

Make Order Cycle Time Your Competitive Edge

Understanding and optimizing order cycle time can give your CPG brand a serious edge. It’s not just about improving speed, it’s about building a system that creates predictability, efficiency and trust.

Even small improvements can lead to smoother operations, happier customers, and stronger growth. Start by auditing your current Order Cycle Time and identifying one change you can implement this week.

By automating order management, integrating data across systems and offering real-time visibility into inventory and orders, Goflow can help you significantly reduce the time it takes to process and fulfill an order.

Want to see it in action? Book a free Goflow demo today!

¹ 49 Cart Abandonment Rate Statistics 2025: https://baymard.com/lists/cart-abandonment-rate