Inventory Turnover Ratio: What It Is, Why It Matters & How to Improve It

Inventory that’s not moving is money you’re not making.

If your products are sitting in storage instead of flying off the shelves, your cash is tied up, your costs are going up, and your growth is slowing down.

That’s where Inventory Turnover Ratio comes in. It’s a key metric that tells you how often you sell and replace your stock over a specific time period. It’s one of the clearest indicators of how efficiently your business is operating.

In this post, we’ll break down what inventory turnover ratio is and why it matters for ecommerce businesses. We’ll also cover what a “good” ratio looks like, what causes it to drop, and how you can improve it with smart replenishment strategies.

What Is Inventory Turnover Ratio?

Inventory turnover ratio tells you how many times your inventory is sold and replaced over a certain time frame. It’s typically calculated monthly, quarterly, or annually.

Here’s the formula:

Inventory Turnover Ratio = Cost of Goods Sold (COGS) / Average Inventory

For example, if:

COGS = $500,000

Average Inventory = $100,000

Then: 500,000 ÷ 100,000 = 5

This means your inventory turned over five times in the past year.

What’s Considered a “Good” Inventory Turnover Ratio?

So, how do you know if your inventory turnover ratio is healthy? The truth is, there’s no universal “perfect number.” A lot depends on your product type, margins and business model. There are, however, helpful benchmarks.

For most ecommerce businesses, a turnover ratio between 4 and 6 is considered healthy

Fast-moving consumer goods often have higher ratios (6–10+)

A very high turnover ratio (10+) might seem great, but it could mean you're constantly understocked, leading to missed sales and unhappy customers

The goal is to find the right balance: move inventory efficiently, but keep enough on hand to meet demand without delays.

Why Inventory Turnover Matters for Ecommerce Sellers

This metric touches nearly every part of your business, from purchasing and warehousing to marketing, product development, and cash flow.

When your turnover ratio is high:

Products are moving quickly

You’re not tying up cash in dead stock

Storage and carrying costs stay lean

When it’s low:

You may be overstocking or misjudging demand

Outdated SKUs are sitting idle

You’re investing in inventory that isn’t paying off

Monitoring this ratio helps you make smarter decisions: what to reorder, when to reorder, and what to cut from your catalog.

What Causes a Decrease in Inventory Turnover?

If your turnover ratio is slipping, it’s often a sign of underlying inefficiencies. Here are a few common causes:

Over-ordering without matching demand, leaving you stuck with excess stock.

Poor-performing products that don’t resonate with your audience.

Inaccurate demand forecasting that leads to misaligned stock levels (see our Forecasting Guide for help.)

Long lead times or supplier delays forcing you to hold extra “safety” inventory.

Seasonal products that linger past their peak.

Inefficient replenishment strategies, like reordering too early or in the wrong quantities.

The upside? All of these are fixable with the right strategy—and the right tools.

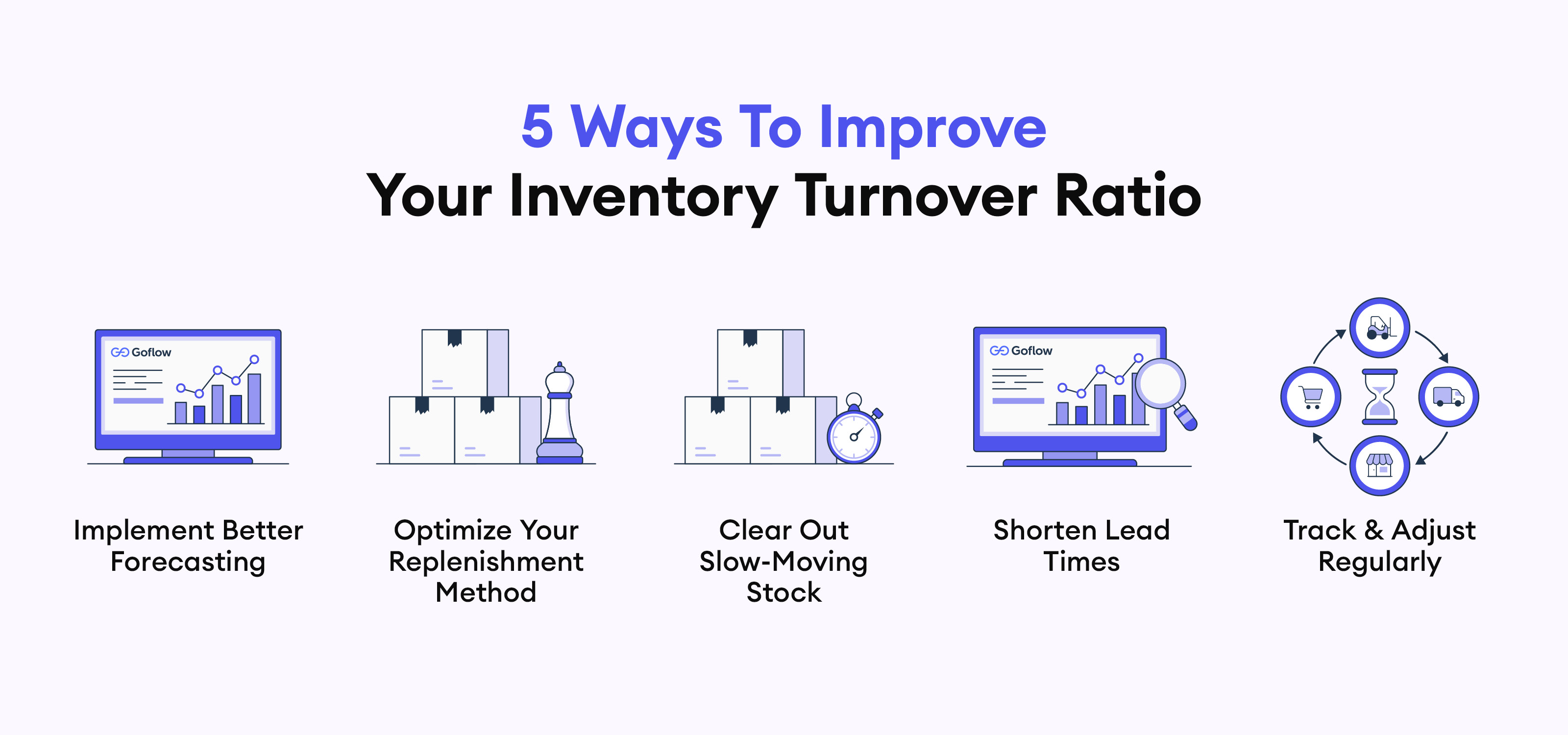

5 Ways To Improve Your Inventory Turnover Ratio

Here are five practical strategies to help you increase turnover and reduce inventory bloat:

1. Implement Better Forecasting

Accurate forecasting is the foundation of healthy turnover. Use historical sales, seasonality trends, and real-time channel data to plan more effectively.

With Goflow, you can automatically consolidate data from all your sales channels and generate real-time inventory reports. Quickly see which SKUs are aging, identify slow movers, and make smarter decisions to stay ahead of demand.

2. Optimize Your Replenishment Method

How and when you restock matters. The right strategy can help you avoid overstocking, reduce shortages, and improve turnover.

Here are three proven approaches:

Fixed Time Period Ordering

With this method, you place orders at regular intervals (weekly, biweekly, monthly, etc.) based on expected demand. It’s easy to schedule and predict, which is great for keeping things simple. But it also assumes demand stays steady. If your sales spike unexpectedly or drop off, you could end up with too much (or too little) stock.Fixed Order Quantity

This approach triggers a restock whenever inventory for a given SKU falls below a set threshold. The quantity ordered stays consistent, which can help stabilize costs and streamline purchasing. However, it depends on having accurate tracking in place so you know when to reorder.Just-in-Time (JIT) Replenishment

JIT is all about ordering only what you need, exactly when you need it. It’s ideal for fast-moving items with predictable demand and short lead times. But it leaves little room for error—delays in the supply chain can quickly cause stockouts.

There’s no one-size-fits-all answer here. The best strategy depends on your product mix, supplier reliability, and how much flexibility your business needs. Many ecommerce sellers find that using a hybrid approach works best.

3. Clear Out Slow-Moving Stock

A sluggish inventory turnover ratio often points to one core issue: too many products that just aren’t selling. These slow-moving SKUs tie up capital, crowd your storage space, and make it harder to focus on what’s actually working.

The good news? You have options—and the sooner you act, the better.

Run promotions, flash sales, or limited-time discounts to move aging inventory quickly. Even small price cuts can trigger sales and free up space.

Bundle slow sellers with fast movers to increase perceived value and boost average order size. It’s a smart way to clear inventory without slashing margins too deeply.

Use ABC analysis to identify C-tier products—the ones contributing the least to your revenue—and decide whether to reorder, reposition, or retire them entirely.

The goal isn’t just to offload old stock. It’s to stay agile. By regularly clearing out underperforming inventory, you keep your operations lean, your cash flow healthier, and your attention focused on high-impact products.

4. Shorten Lead Times

Long lead times can quietly sabotage your inventory turnover. When it takes too long to receive new stock, you’re left with two risky options: run out of your bestsellers and lose sales, or overstock “just in case,” tying up cash and shelf space. Neither scenario is ideal.

Reducing lead times helps you stay flexible and responsive to demand. Here’s how to do it:

Work with faster or more local suppliers who can deliver smaller batches more frequently. This lowers your reliance on large, infrequent shipments that bog down your operations.

Strengthen relationships with manufacturers so you can stay ahead of delays, adjust timelines as needed, and troubleshoot issues before they impact fulfillment.

Automate your purchase orders to cut down manual processing time and respond to inventory changes in real time.

Every day you shave off your lead time gives you more agility. The faster your stock moves through the supply chain, the faster it turns into revenue.

5. Track & Adjust Regularly

Inventory turnover isn’t something you calculate once and forget about. It’s a dynamic metric that reflects the current state of your business, and it needs to be reviewed regularly.

Make it a habit to monitor your turnover rate monthly or quarterly. Watch for shifts in sales velocity, seasonality, or supplier performance, and adjust your replenishment, pricing, or forecasting strategies accordingly.

With Goflow, you can track turnover in real time across every warehouse, product, and channel. Built-in dashboards make it easy to spot trends, flag slow movers, and pivot fast, so you're always operating with up-to-date insights, not outdated assumptions.

A Healthy Inventory Turnover Ratio = A More Efficient Business

A healthy inventory turnover ratio leads to better cash flow, fewer carrying costs, and a more agile business. It’s one of the most important KPIs you can track, alongside others like Inventory-to-Sales Ratio, Sell-Through Rate, and Carrying Cost of Inventory.

With Goflow, you’ll gain the insights and tools you need to manage inventory like a pro: forecast accurately, restock efficiently, and clear slow movers with confidence.

Ready to see it in action? Book a Goflow demo.