Inventory Management Tips for Subscription Ecommerce Businesses

Running a subscription ecommerce business means you’re not just selling products, you’re delivering on a promise, month after month.

That promise adds pressure. Subscribers expect their boxes or replenishments to arrive on time, every time. A late or missed shipment doesn’t just cause disappointment, it risks cancellations, churn, and even negative reviews that hurt long-term growth.

But there’s an upside too: subscriptions give you something most ecommerce sellers only dream of: predictability. You have built-in demand signals, recurring revenue, and the chance to develop long-term relationships with loyal customers. The challenge is making sure your operations and inventory management processes can keep pace with that responsibility.

The good news? With smart inventory management, subscription sellers can stay ahead of demand, prevent stockouts, and keep customers loyal.

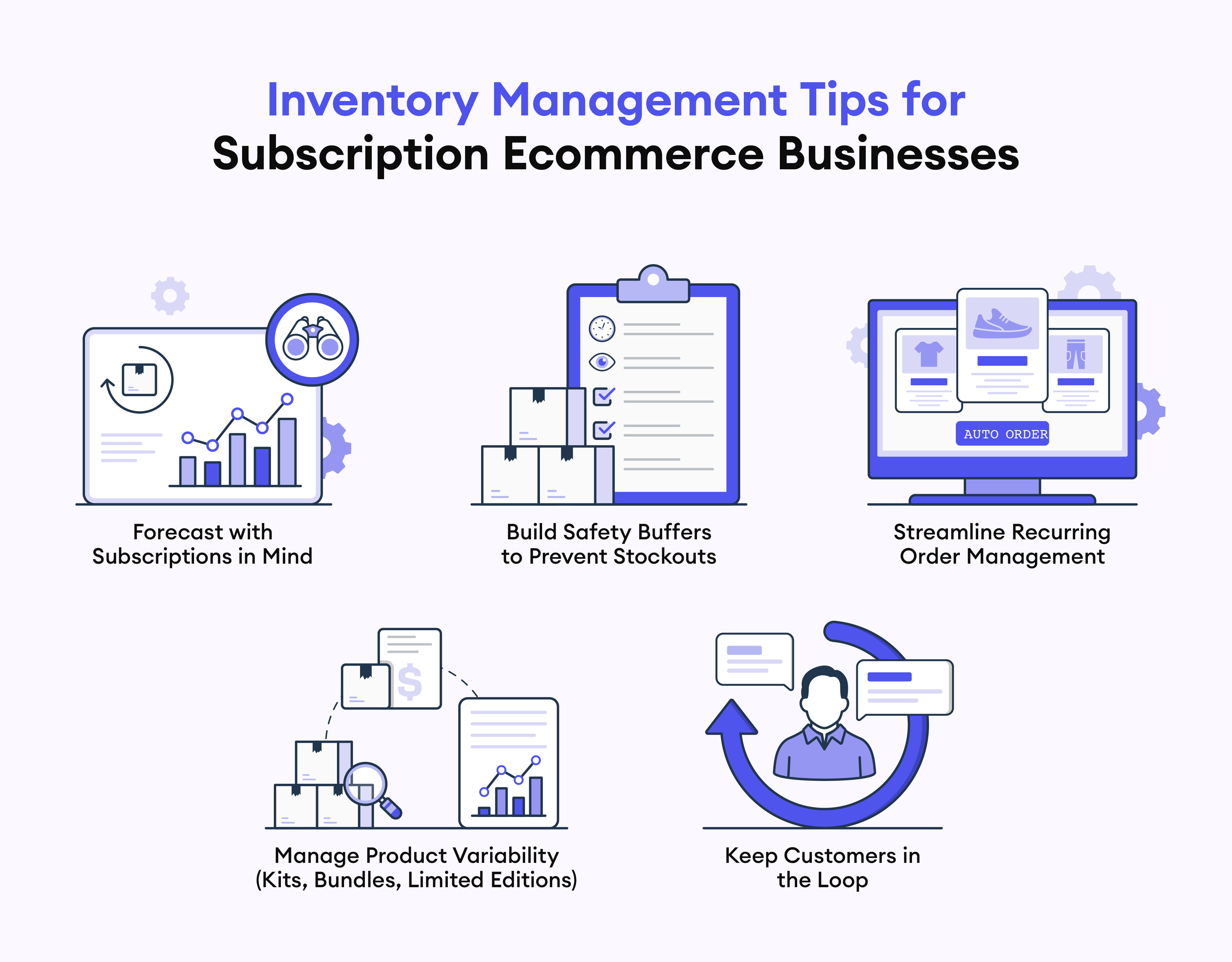

Here are five practical strategies to strengthen your inventory process for subscription models.

1. Forecast with Subscriptions in Mind

Unlike one-off purchases, subscriptions give you a built-in demand signal: your subscriber count. Use that to your advantage.

Plan around renewal cycles. Monthly, quarterly, or seasonal timelines should guide your forecasting. For example, if you run a monthly snack box, your biggest spike will always happen at the start of each cycle.

Use historical data. Look back at churn and growth trends. Did you see a jump after last year’s holiday promotions? Do some products have seasonal demand curves?

Factor in spikes. Promotions, influencer campaigns, or a TikTok trend can cause unexpected short-term lifts in demand. Build a cushion into your forecast so you’re ready to capture a spike in interest.

Pro tip: Don’t just look at total subscribers. Break down active, paused, and at-risk accounts. If you know churn typically averages 5% but growth campaigns add 10% new customers, you can plan with much greater accuracy.

When you forecast specifically for recurring orders, you avoid scrambling to restock at the last minute.

Want a deeper dive into predicting demand beyond subscriber counts? Check out our post Inventory Forecasting Guide: How To Predict Demand. It shows you how to anticipate trends, seasonal spikes and other factors that impact inventory planning.

2. Build Safety Buffers to Prevent Stockouts

In subscription ecommerce, a stockout stings more than a late one-off order. Missed deliveries break trust. Once trust is gone, cancellations usually follow.

To reduce risk:

Carry buffer stock for your most popular SKUs. Even an extra 5–10% over projected demand can protect against surprises.

Account for supplier lead times. If it takes your supplier six weeks to restock, build that into your buffer planning. Don’t assume replenishment will always arrive “just in time.”

Use real-time visibility tools. Low stock alerts give you time to reorder before it becomes an emergency.

Think of safety stock as insurance. It may feel like extra cost up front, but the expense of losing subscribers far outweighs the price of carrying a small surplus.

With Goflow, you’ll see low stock alerts before they become fulfillment problems, giving you time to adjust.

3. Streamline Recurring Order Management

Getting your order management system right will help you to reduce errors, lower labor costs and make sure fulfillment stays on schedule.

Automate order creation so every cycle is triggered without manual effort.

Segment subscribers (monthly vs. quarterly) to smooth out fulfillment waves instead of facing one overwhelming crunch.

Batch process orders to save time. For example, instead of packing 500 boxes individually in random order, group them by renewal date and process in batches.

For a deeper dive into getting the best results from your order management system, check out this blog post: HowTo Set Up an Order Management System (OMS) That Scales With Your Ecommerce Business.

4. Manage Product Variability (Kits, Bundles, Limited Editions)

Subscription models often include rotating products, bundled kits, or limited-edition items. These delight customers but add complexity behind the scenes.

Maintain accurate BOMs (bill of materials) so every box is accounted for down to the last component.

Track bundle components individually in your system to avoid shortages. If a holiday box requires 5 separate SKUs, you need visibility into all five, not just the final package.

Forecast limited editions carefully. Use opt-in percentages from past campaigns. If 30% of subscribers usually add the “deluxe upgrade,” plan stock accordingly.

The goal is simple: never promise what you can’t deliver. Nothing disappoints customers more than being excited for a limited-edition item that gets delayed or canceled because of inventory mismanagement.

If you handle perishable or time-sensitive products in your subscriptions, you might find our post Managing Perishable Inventory: How To Keep Things Fresh & Avoid Waste especially useful. It covers tracking, spoilage prevention and inventory optimization for products with limited shelf life.

5. Keep Customers in the Loop

Inventory management doesn’t end at the warehouse, it extends to customer communication. It’s better to notify your customers as early as possible if there’s any risk of delay. A proactive email builds trust, but a last-minute apology email erodes it by making you look unprofessional and unprepared.

Offer alternatives or substitutions when possible. If one flavor is out of stock, a replacement with a small bonus item can soften the blow. Also, customers are more forgiving when they know what’s happening, so transparency and honesty are your secret weapons here. .

Example:

Bad communication: “Sorry, your box is delayed. We’ll let you know when it ships.”

Good communication: “Your September box is running a day behind because one product was delayed in transit. It will ship tomorrow, and we’ve added a bonus item as a thank you for your patience.”

Proactive communication can reduce churn and build trust with your customer base, even when something goes wrong.

Common Pitfalls to Avoid

Here are a few potential mistakes to watch out for that could derail operations:

Relying only on subscriber counts without forecasting growth. New sign-ups or gift subscriptions can spike unexpectedly.

Forgetting to account for churn or skipped months. Not every subscriber renews or participates every cycle. Factor this into your planning.

Skipping regular reconciliation. Without routine cycle counts, you might not catch shortages until it’s too late.

Rotating SKUs without updating bundles. One missing component can derail hundreds of shipments.

Each pitfall is avoidable with better data, clear processes, and the right tools.

Final Thoughts

Subscription businesses face unique inventory challenges, but they’re solvable. Forecasting, safety buffers, automation, product tracking, and proactive communication all play a role in keeping operations smooth. More importantly, they protect the real value of subscriptions: the customer’s trust.

When you deliver on time, every time, you don’t just fulfill an order, you reinforce a relationship. That trust compounds into retention, referrals, and predictable recurring revenue.

With Goflow, subscription ecommerce sellers can:

Track stock in real-time.

Automate recurring orders.

Maintain consistent, on-time delivery cycles.

That way, you can keep your promise to subscribers and keep them coming back month after month. Want to see how it works? Book a live customized demo and see Goflow in action.