How Do I Get Started With Inventory Management?

Imagine this: A small online store doesn't have an inventory tracking system set up.

Suddenly, everyone wants their best-selling product, but they don't realize they're running low. They can't fulfill orders, so customers get mad and sales are lost. Meanwhile, they have too much of a product that no one's buying, wasting money and space. This shows how important good inventory management is for keeping customers happy and preventing lost sales.

Sound familiar? Many Ecommerce business owners face these same issues. The good news? These problems are preventable.

The key to overcoming them lies in setting up an inventory management system correctly from the start. In this guide, we’ll walk you through the crucial first step: inventory control. By mastering this foundational process, you’ll set yourself up for success and create a solid foundation for efficient, profitable inventory management.

What is Inventory Management and Why Is It Important?

Inventory management is basically keeping track of what you have in stock. It means knowing how much stock you have, predicting what people will want, and deciding when and how much to order.

The goal is to have the right products available at the right time, without spending too much money or wasting resources. Effective inventory management is critical for avoiding costly pitfalls like overstocking, stockouts, and inefficiencies.

By keeping the right amount of stock, businesses can enjoy benefits like:

Better Cash Flow: Having the right amount of inventory frees up cash that would be tied up in extra stock.

More Sales: Making sure products are available helps meet customer demand and take advantage of sales opportunities.

Happier Customers: Getting orders out on time and having products available makes customers happy and keeps them coming back.

Lower Costs: Efficient inventory management saves money on storage, reduces waste, and lowers the risk of products becoming outdated.

Smarter Decisions: Accurate inventory data helps businesses make good decisions about buying, pricing, and marketing.

What is The First Step Of Inventory Management?

So, what’s the first thing you need to do to manage your inventory effectively? It all starts with inventory control. “Inventory Management” covers a wide range of business operations across your entire supply chain and product life cycle, but “Inventory Control” focuses specifically on making sure that the methods, systems and policies you use to manage stock levels are working as efficiently as possible.

Inventory control sets you up for success by making sure your stock levels are accurate, so you don’t have to worry about discrepancies between what’s recorded and what’s actually in stock.

Inventory Control: The Key to Success

Inventory control starts with establishing current stock levels to gain a clear picture of what you have in your inventory and the baseline of where you’re starting from. This is crucial for knowing what you have and what’s selling, so you can start building out an inventory management strategy that is based on a realistic assessment.

Why is this important?

Knowing what you have helps identify fast-moving and slow-moving items.

It enables you to set realistic reorder points.

It provides a baseline for tracking inventory turnover rates.

It’s also essential to establish a system that records inventory movement automatically, so that your stock levels will be updated in real time.

What Methods or Tools Can Ecommerce Sellers Use to Determine Stock Levels?

The first step in Inventory Control is performing a stock take, which is a physical count of all your inventory. Doing this by hand might work for a small operation, it’s prone to human error. If you can, use digital tools like barcode scanners or inventory software. It’s much faster and more accurate, which saves you time and money.

Ideally, a stock take should be as detailed as possible. The purpose is to get an accurate idea of the company's recorded stock levels, so that you can understand how efficiently you're tracking inventory and improve your inventory management processes.

Stocktaking Best Practices

Stocktaking Best Practices

Count everything: Seriously, everything – raw materials, stuff you're working on, finished products. Check all your storage spots.

Use software like Goflow: It tracks your inventory in real-time so you don't have to keep counting manually.

Schedule regular stocktakes: How often depends on your business, but do it regularly to keep your records straight.

Compare your physical count with your inventory system: This helps find mistakes and things you can improve. If your physical count and your system don't match, figure out why and fix it.

Keep in mind that a stock take isn’t something that just happens once. You should have a way of regularly assessing your stock levels so you’re always aware of what you have. With Goflow or other similar inventory management tools, you can get comprehensive inventory reports anytime so you’ll always know exactly how much stock you have without the hassle of manual tracking.

Common Inventory Assessment Challenges & How to Avoid Them

Doing your first inventory assessment can be difficult and there are many challenges that businesses often run into. Let’s take a closer look at some of these problems and how you can fix them.

Manual Tracking Errors

The Problem: Keeping track of inventory by hand is a recipe for mistakes. Miscounts, wrong data entry, and calculation errors can mess up inventory records. These inaccuracies can lead to running out of stock, having too much stock, and losing sales.

The Solution: Inventory management software like Goflow uses automation to reduce human errors and improve accuracy. Barcode scanning, RFID technology, and automated data entry make sure inventory counts are accurate and reliable.

Data Integration Issues

The Problem: Lots of businesses operate across multiple sales channels, warehouses, and departments. Keeping inventory data in sync across all these platforms can be tough. Manual data entry and different systems can lead to inconsistencies and outdated information.

The Solution: Modern inventory management systems work with various sales channels, e-commerce platforms, and ERP systems. This integration allows for smooth data flow, making sure that inventory information is consistent and up-to-date across all channels. Goflow allows for centralized data that provides real-time visibility into stock levels across all channels, ensuring everyone has access to the same real-time information.

Lack of Real-Time Insights

The Problem: Traditional inventory management methods often rely on periodic stocktakes and manual updates. This lack of real-time visibility can make it hard to respond to changes in demand and supply. Stockouts, overstock, and missed sales opportunities can result from this lack of insight.

The Solution: Advanced inventory management software like Goflow provides real-time inventory sync features that ensure inventory is always up-to-date in real time and synchronized with sales and supplier systems. As soon as a sale is made or a shipment arrives, the inventory levels are automatically updated. This real-time visibility lets businesses make informed decisions, optimize stock levels, and avoid costly inventory issues.

Case Study: Jeannie N Mini LLC

Jeannie N Mini LLC is a kids boutique store in Orange County, California. In business for 12 years, the store operates both brick-and-mortar shops as well as online stores, with a product range that covers everything from baby toys to toddlers shoes to beauty products, skincare and organic teas. Their products are available across multiple marketplaces, including Amazon, Nordstrom, Target and Macy’s.

Before using Goflow, Jeannie operated multiple Shopify stores and her warehouse team had to manually go through each website throughout the day to process the orders. They had to perform separate inventories for each channel, which was time-consuming and error-prone. After switching to Goflow, owner Jeannie Yoon was able to centralize her inventory data, saving time and improving accuracy.

Read More About How Goflow Helped Jeannie Achieve 2.5x Sales Growth

After Determining Current Stock Levels: What’s The Next Step?

So you’ve gotten a handle on your stock levels - now what? Here’s what you can do next:

So you’ve gotten a handle on your stock levels - now what? Here’s what you can do next:

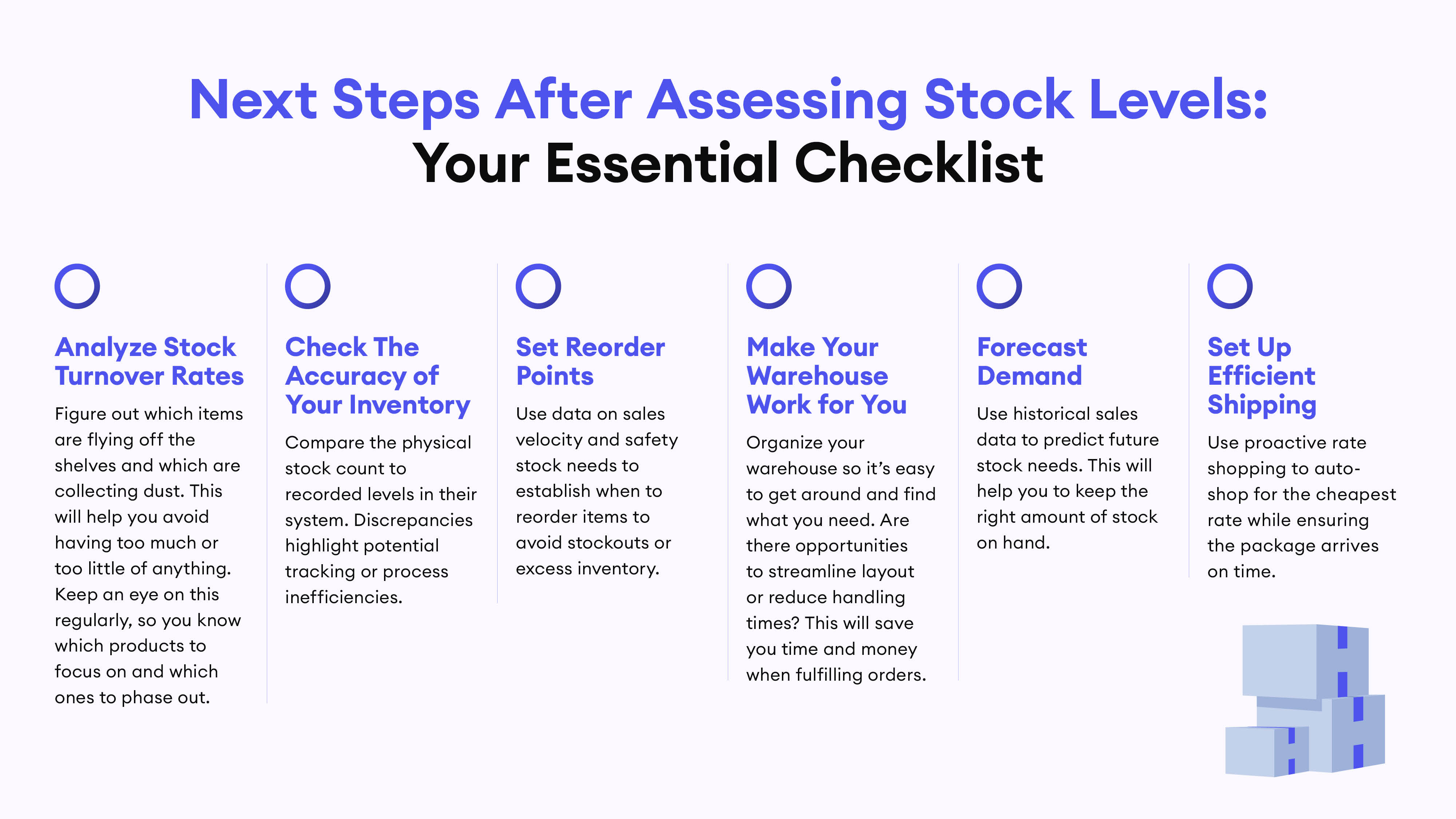

Analyze Stock Turnover Rates: Figure out which items are flying off the shelves and which are collecting dust. This will help you avoid having too much or too little of anything. Keep an eye on this regularly, so you know which products to focus on and which ones to phase out.

Check The Accuracy of Your Inventory: Compare the physical stock count to recorded levels in their system. Discrepancies highlight potential tracking or process inefficiencies.

Set Reorder Points: Use data on sales velocity and safety stock needs to establish when to reorder items to avoid stockouts or excess inventory.

Make Your Warehouse Work for You: Organize your warehouse so it’s easy to get around and find what you need. Are there opportunities to streamline layout or reduce handling times? This will save you time and money when fulfilling orders.

Forecast Demand: Use historical sales data to predict future stock needs. This will help you to keep the right amount of stock on hand.

Set Up Efficient Shipping: Use proactive rate shopping to auto-shop for the cheapest rate while ensuring the package arrives on time.

The Key to Effective Inventory Management

As Peter Drucker famously said, “If you can’t measure it, you can’t improve it.” Accurate inventory control is the foundation of effective inventory management, and keeping tabs on your inventory is the first step to having a handle on it. By starting with a clear understanding of your current stock levels, you can establish a robust system that gets rid of waste and brings in more cash flow.

Tools like Goflow help ecommerce sellers manage their inventory without the headaches. Real-time updates and automation take out the guesswork, so you can make smarter decisions, reduce manual errors and focus on growing your business. Take the first step today by assessing your inventory and setting up an ecommerce inventory management system designed for success.