Black Friday, Cyber Monday: How to Streamline Multi-Channel Ops for Peak Performance

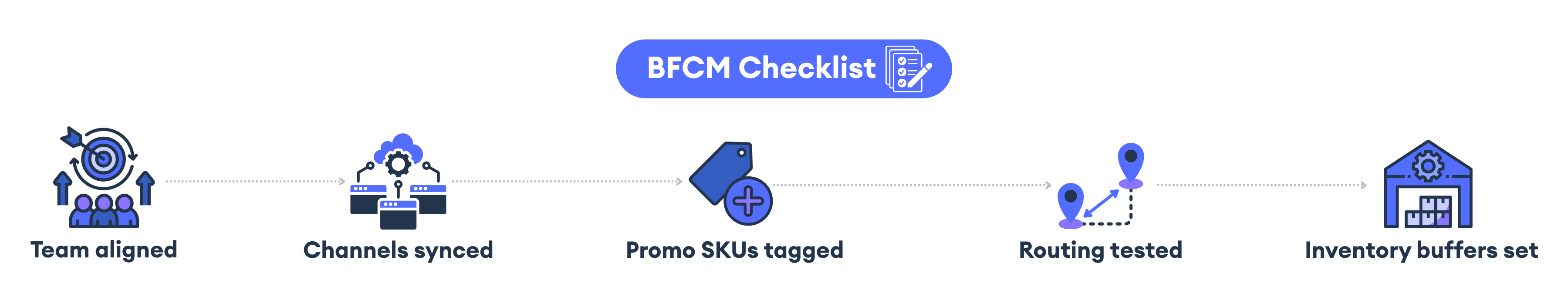

Ready for the rush? Keep your channels, inventory, and fulfillment in sync when BFCM puts your ops to the test.

.png)

Black Friday and Cyber Monday aren’t just high-traffic weekends. They’re an operational stress test.

Every channel moves at once. Listings update, orders spike, warehouses fill, and fulfillment rules fire nonstop. It’s not just about having enough stock; it’s about keeping everything connected so your systems scale smoothly when the pressure hits.

Peak season doesn’t reward hustle. It rewards alignment.

Here’s how to make sure your entire multi-channel operation — from listings to logistics — is ready for the rush.

1. Sync Every Channel Before You Sell

Nothing derails Black Friday momentum faster than mismatched listings, missing SKUs, or outdated stock counts. When shoppers flood your pages, you need total confidence that every channel reflects reality.

How to get aligned:

Audit all active channels for duplicate listings, missing attributes, or broken variations.

Use Goflow to centralize product data management so pricing and promotions update in real time.

Verify that your OMS or multi-channel operating system (like Goflow) syncs inventory, pricing, and fulfillment rules across 3P, 1P, and DTC models.

Where Goflow helps:

Goflow connects every channel — Amazon, Walmart, Shopify, Target Plus, and 250+ more — so updates flow automatically. Listing errors are flagged before they go live, and every SKU stays in sync.

Pro Tip:

Before you launch a big promo, confirm that each SKU has a defined fulfillment path — whether it ships from FBA, a 3PL, or your own warehouse. That 10-second check can save hours of chaos later.

2. Prep Your Fulfillment Network for the Surge

Your biggest risk during BFCM isn’t stock — it’s routing. Orders will flood in from every direction, and manual workarounds won’t cut it.

How to stay ahead:

Test your routing logic to ensure high-volume SKUs flow to the fastest or most cost-efficient fulfillment location automatically.

Confirm backup carriers, service levels, and packaging rules for each marketplace.

Pre-kit or pre-label your top sellers to speed up pick-and-pack times.

Where Goflow helps:

Goflow automates order routing to the best fulfillment option — FBA, WFS, 3PL, or your own DC — based on inventory, cost, and proximity to the customer. It also syncs tracking updates to every channel automatically.

Pro Tip:

Some marketplaces don’t allow Amazon-branded packaging. Set up non-Amazon boxes and custom shipping rules early. Goflow can automate that switch right inside your FBA settings.

Want a deeper dive into speeding up fulfillment before the surge hits? Read our post Reducing Lead Time: How to Speed Up This Important KPI. It shows how small improvements in process and coordination can cut hours from every shipment — and keep your network flowing even when orders spike.

3. Keep Inventory Visibility Unified

3. Keep Inventory Visibility Unified

Stockouts and oversells aren’t just annoying — they’re expensive. A single disconnect between systems can cause canceled orders, poor seller ratings, and missed revenue across every channel.

How to prevent it:

Use one real-time source of truth for inventory across your channels.

Automate reorder triggers for fast-moving SKUs.

Build live dashboards that flag low-stock or high-velocity products before they become a problem.

Where Goflow helps:

Goflow keeps your stock accurate everywhere in real time — adjusting buffers per channel, tracking bundles, and syncing quantities instantly. You’ll know exactly what’s available, where it’s stored, and how fast it’s moving.

Pro Tip:

During BFCM, monitor your top 20 SKUs multiple times a day. Small adjustments early can prevent major losses later.

4. Align Promotions and Operations

Great marketing only works when your operations can keep up. Every campaign should be grounded in what your systems can actually fulfill.

How to stay coordinated:

Sync your promo calendar with supplier lead times and warehouse capacity.

Tag SKUs by promo priority so your team can fulfill them faster.

Pause ads or dynamic pricing on low-stock items to avoid oversells and refunds.

Where Goflow helps:

Because Goflow connects your inventory, listings, and order data in one system, your marketing team always sees live stock counts. No more promoting what you can’t ship; Goflow ensures promos and inventory stay perfectly aligned.

Pro Tip:

Run a “systems rehearsal” two weeks before BFCM — a short flash sale across all channels. Watch how your inventory updates, orders route, and fulfillment performs under pressure. Then fine-tune before the real thing.

5. Plan for the Aftermath

Peak season doesn’t end when Cyber Monday does. The weeks that follow bring returns, restocks, and reconciliation — and the smartest sellers plan for that too.

How to stay in control:

Automate your returns and restocking workflows by channel.

Compare forecasted vs. actual sales to identify accuracy gaps.

Use post-holiday insights to refine next year’s forecasting and allocation.

Where Goflow helps:

Goflow centralizes return data, updates restocked quantities automatically, and surfaces performance analytics, showing which SKUs drove profit and which caused headaches. That means faster decisions, cleaner data, and better inventory forecasting next time.

Pro Tip:

BFCM is your best data source of the year. Analyze what moved fastest, what sold through cleanly, and what got returned the most. Those insights will shape your next quarter — and next peak — for the better.

The Bottom Line

Black Friday and Cyber Monday expose every weak point in an operation. Listings, inventory, fulfillment, and communication all have to move as one.

When your systems stay in sync, the weekend stops feeling like a scramble and starts running like a machine. You can scale without breaking pace — because every part of your operation is pulling in the same direction.

Peak season isn’t about luck or hustle. It’s about alignment.

Get your systems there before the rush hits.

Book a demo to see how.